The post Acrylic CNC Machining Services: Clarity, Precision, and How to Get It Right appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post Acrylic CNC Machining Services: Clarity, Precision, and How to Get It Right appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post 304 vs 316 Stainless Steel: What’s the Difference and Which Should You Use? appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post 304 vs 316 Stainless Steel: What’s the Difference and Which Should You Use? appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post Thermoset vs Thermoplastic: Definition, Processes, and Key Differences appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post Thermoset vs Thermoplastic: Definition, Processes, and Key Differences appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post Alloy Steel vs Carbon Steel: What’s the Difference and When to Use Each? appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post Alloy Steel vs Carbon Steel: What’s the Difference and When to Use Each? appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

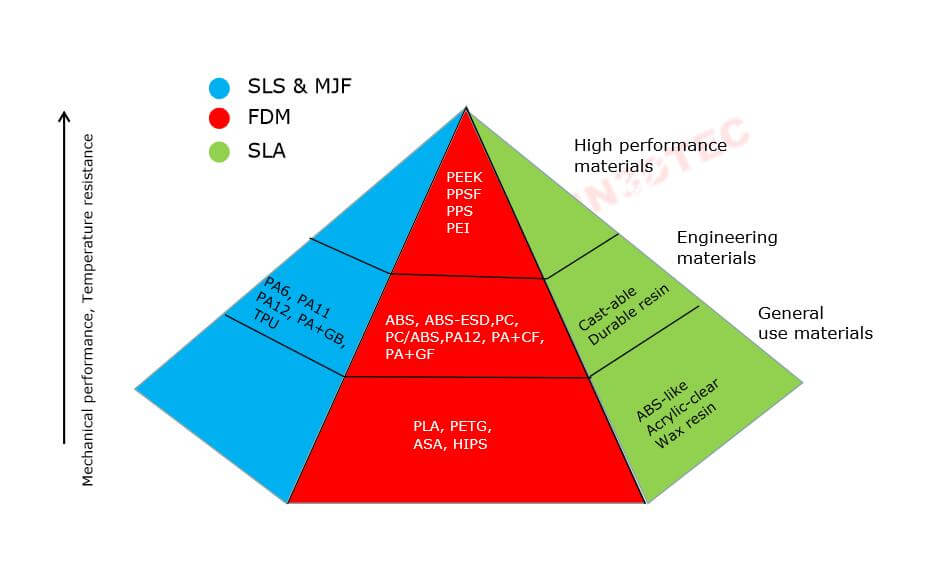

]]>The post FDM vs. SLA vs. SLS: Which 3D Printing Technology Should You Choose? appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post FDM vs. SLA vs. SLS: Which 3D Printing Technology Should You Choose? appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

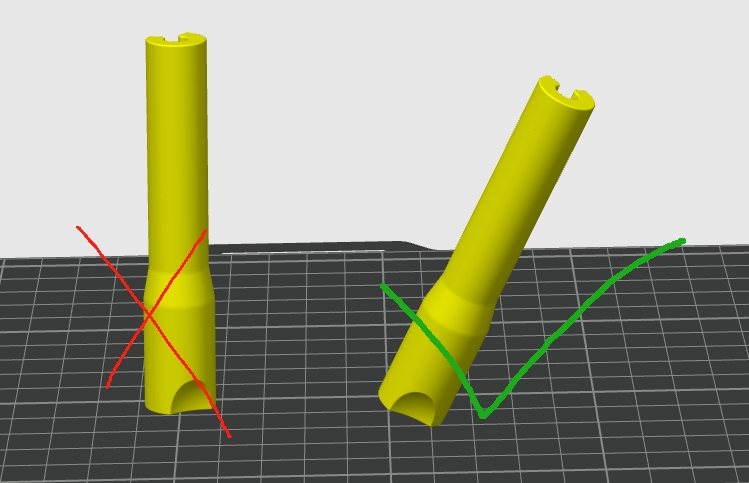

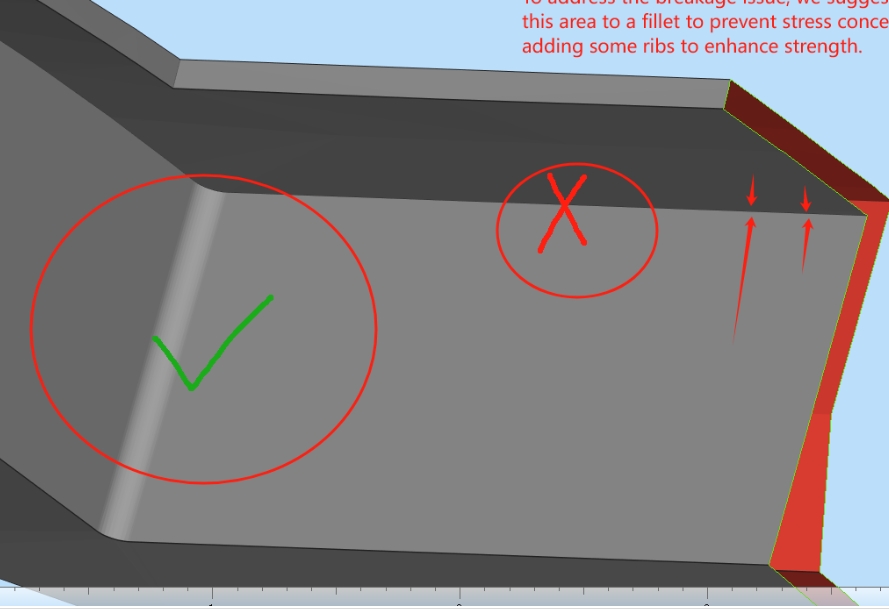

]]>The post Top 5 Design Tips for Stronger 3D Printed Parts appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post Top 5 Design Tips for Stronger 3D Printed Parts appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post How 3D Scanning is Revolutionizing Automotive Restoration appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post How 3D Scanning is Revolutionizing Automotive Restoration appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post Sustainable Solutions: Biodegradable 3D Printing Materials and Services appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post Sustainable Solutions: Biodegradable 3D Printing Materials and Services appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post How to Electroplate SLS Nylon 3D Prints: A Guide to Metallic Finishes appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post How to Electroplate SLS Nylon 3D Prints: A Guide to Metallic Finishes appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post What to Consider When Selecting a Metal 3D Printing Service appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post What to Consider When Selecting a Metal 3D Printing Service appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

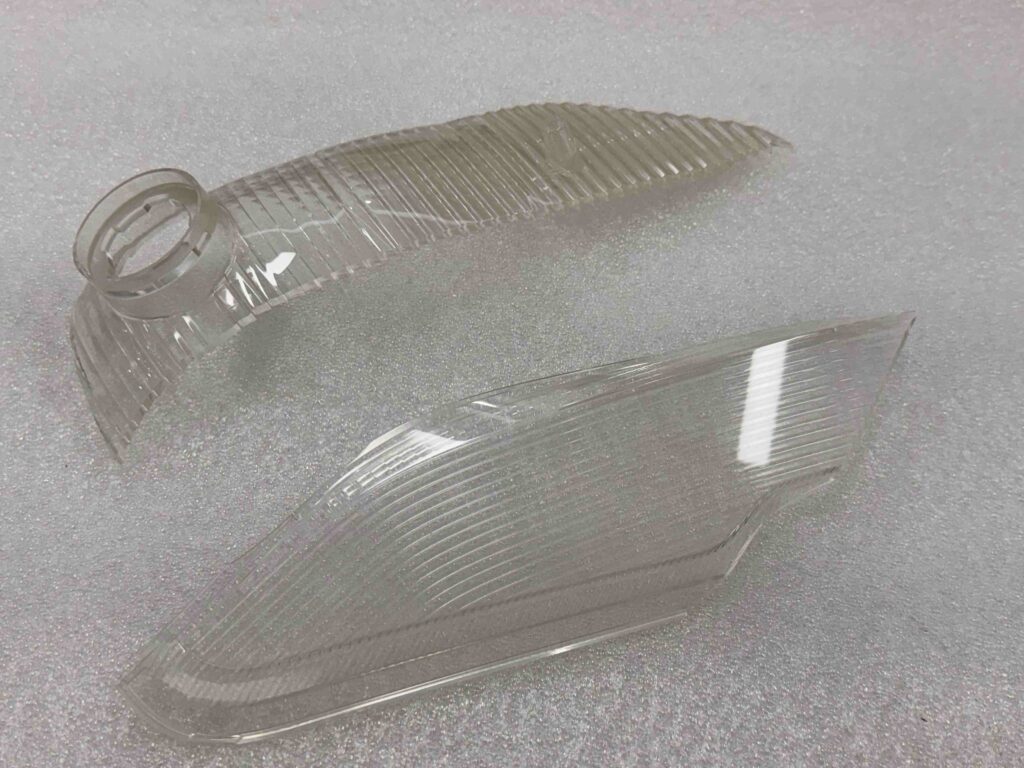

]]> High optical clarity

High optical clarity