The post FDM vs. SLA vs. SLS: Which 3D Printing Technology Should You Choose? appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>FDM vs. SLA vs. SLS: Which 3D Printing Technology Should You Choose?

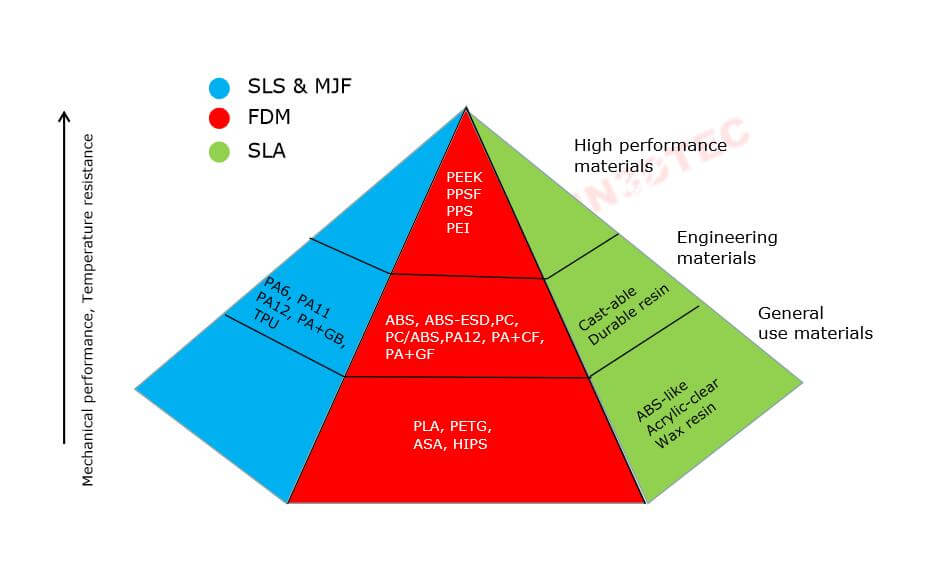

When it comes to 3D printing, choosing the right technology can make a big difference in the success of your project. Among the most commonly used 3D printing technologies are FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering). Each has its strengths, weaknesses, and ideal use cases. In this article, we break down the differences to help you make an informed decision.

FDM (Fused Deposition Modeling)

FDM is the most widely used 3D printing method, especially for rapid prototyping and low-cost applications.

Printable materials in FDM: ABS,ASA, Carbon fiber, PETG, PLA, PC, PP, PEEK, PPS, PPSU, PEI, POM, NYLON12/66, TPU/TPE(70A, 85A, 92A, 98A, 65D all are available from IN3DTEC 3D printing service)

Pros:

Cost-effective and widely accessible

Easy to operate and maintain

A wide range of thermoplastics available.

Good for functional prototypes and low-tolerance parts

Cons:

Lower resolution and surface finish compared to SLA and SLS

Visible layer lines

Limited geometric complexity

Best for: Quick and affordable prototypes, basic mechanical parts, early-stage product development, fixtures and jigs

Applications:

Consumer product housings

Automotive test parts

Educational and concept models

Jigs and fixtures

SLA (Stereolithography)

SLA uses a UV laser to cure liquid resin into solid parts and is known for its high precision and fine details.

Printable materials in SLA: Standard ABS, Tough ABS, Somos Evolve, Somos Ledo, Somos Taurus, Ceramic

Pros:

Excellent resolution and surface finish

Ideal for detailed, intricate designs

Tight tolerances and minimal post-processing

Cons:

More expensive than FDM

Brittle material properties

Limited selection of resins compared to FDM thermoplastics

Best for: Highly detailed models, dental and medical components, visual prototypes, and molds

Applications:

Dental molds and aligners

Housing & Casings for all products

Jewelry prototypes

Medical device casings

High-detail display models

SLS (Selective Laser Sintering)

SLS uses a laser to fuse powdered materials (usually nylon) into solid parts. It does not require support structures, making it suitable for complex geometries.

Printable material in SLS: Nylon, Nylon+GF, Nylon+CF, PP, PEEK, TPU

Pros:

Strong, functional parts with good mechanical properties

No need for support structures

Excellent for complex assemblies and interlocking parts

Cons:

Higher cost and equipment complexity

Rough surface finish that may require post-processing

Longer lead times

Best for: End-use parts, mechanical components, small-batch production, functional prototypes

Applications:

Aerospace brackets and housings

Medical equipment components

Functional gears and hinges

Drone and robotics parts

Which Should You Choose?

Choose FDM if you’re looking for an affordable and fast option for early-stage designs or mechanical parts that don’t require high precision.

Go with SLA when you need fine details, smooth surfaces, or prototype models for presentation or fit testing.

Opt for SLS if you’re producing functional, load-bearing parts with complex geometries or small production runs.

Still unsure? Reach out to our team through [email protected] —we’ll help match your design with the right technology based on your budget, timeline, and performance requirements.

The post FDM vs. SLA vs. SLS: Which 3D Printing Technology Should You Choose? appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post Top 5 Design Tips for Stronger 3D Printed Parts appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>Top 5 Design Tips for Stronger 3D Printed Parts

Whether you’re creating prototypes or functional end-use components, ensuring strength and durability in your 3D printed parts is essential. Good design can significantly enhance part performance, reduce failure rates, and make your prints more reliable. Here are the top 5 design tips to help you get stronger, more resilient 3D printed parts.

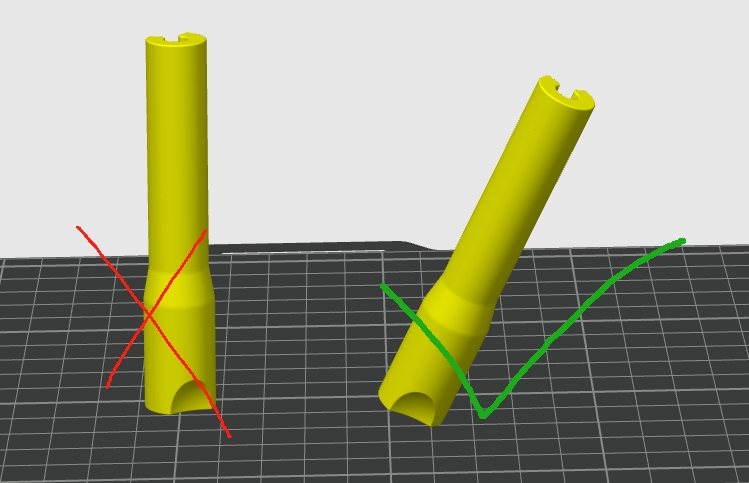

- Optimize Print Orientation

Layer adhesion is typically the weakest point in any 3D printed part. To maximize strength, orient your part so that the layers run perpendicular to the direction of the applied forces. For example, if the part will endure vertical stress, consider printing it lying down so the layers stack horizontally relative to the stress.

Pro Tip: Use simulation tools to predict stress points and align your model accordingly.

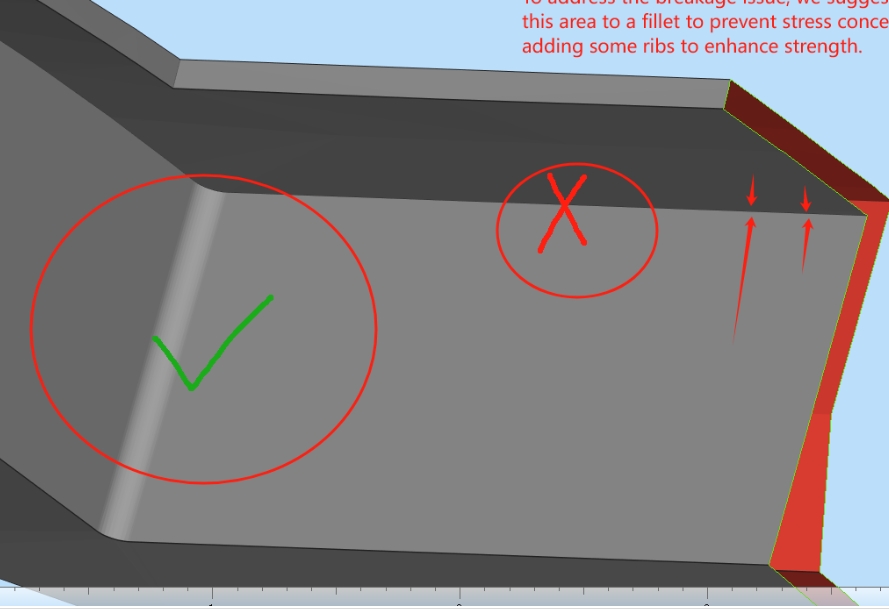

- Use Fillets Instead of Sharp Corners

Sharp corners create stress concentration points which can lead to cracking. Adding fillets (rounded edges) not only improves the strength by distributing stress more evenly but also enhances the printability by reducing potential printing errors.

Pro Tip: A fillet radius of 1-2 mm is often sufficient for improving part integrity.

- Increase Wall Thickness and Infill Density

One of the simplest ways to strengthen your part is by adjusting wall thickness and different infill settings. A thicker shell and higher infill percentage will create a sturdier structure. However, this also increases material use and print time, so find a balance based on your part’s function.

Pro Tip: For functional parts, use at least 2 mm wall thickness and 50% infill or higher.

- Add Ribs and Gussets for Structural Support

Instead of just increasing infill, adding structural features like ribs (vertical walls) and gussets (triangular supports) can reinforce weak sections without significantly increasing weight or print time. These features are especially helpful in load-bearing areas.

Pro Tip: Integrate ribs along flat surfaces or near holes to reduce flex.

- Choose the Right Material

Material selection is key. PLA might be easy to print, but it lacks the toughness of materials like PETG, ABS, or Nylon. If you’re printing functional parts that will be stressed, exposed to impact, or require flexibility, choose a material that meets those needs.

Pro Tip: Consider carbon fiber-reinforced filaments for high-stress, lightweight applications.

Read more: Material Select Guide for 3D Printing

Conclusion

Stronger 3D printed parts begin with smarter design choices. By carefully considering print orientation, geometry, and material selection, you can significantly enhance the performance and longevity of your parts. Have a part you’re designing? Contact us to review your files and recommend the best settings and materials for maximum strength.

The post Top 5 Design Tips for Stronger 3D Printed Parts appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post Sustainable Solutions: Biodegradable 3D Printing Materials and Services appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>Sustainable Solutions: Biodegradable 3D Printing Materials and Services

In recent years, the push for sustainability has permeated various industries, and 3D printing is no exception. As we become increasingly aware of the environmental impact of traditional manufacturing processes and materials, biodegradable 3D printing materials and services have emerged as a viable solution. This blog explores the benefits, applications, and future potential of these eco-friendly alternatives.

What Are Biodegradable 3D Printing Materials?

Biodegradable 3D printing materials are designed to break down naturally over time, reducing their impact on landfills and the environment. Unlike conventional plastics, which can take hundreds of years to decompose, biodegradable materials are made from renewable resources and can disintegrate into harmless substances when exposed to the right conditions.

Common Biodegradable Materials

- PLA (Polylactic Acid):Derived from corn starch or sugarcane, PLA is one of the most popular biodegradable filaments. It is easy to print and can produce high-quality prints, making it a favorite among hobbyists and professionals alike.

- PHA (Polyhydroxyalkanoates): This material is produced by microorganisms and offers excellent biodegradability. PHA is more flexible and durable than PLA, making it suitable for various applications.

- PBS (Polybutylene Succinate): A less common option, PBS is another biodegradable alternative that provides good thermal stability and mechanical properties.

- PA2200(PA12):PA2200is a white, powder-based nylon and biodegradable material (Polyamide 12) commonly used in Selective Laser Sintering (SLS) 3D printing. Known for its excellent mechanical properties, high chemical resistance, and lightweight durability, this material is available on IN3DTEC online 3D printing store.

- PEEK: PEEK (Polyether Ether Ketone)is a high-performance, thermoplastic polymer renowned for its exceptional strength, chemical resistance, biodegradable and thermal stability. It is often used in demanding applications where high temperatures and harsh environments are involved. PEEK is known for its outstanding mechanical properties and is widely regarded as one of the most durable and versatile engineering plastics.PA2200 is a versatile choice for both functional prototypes and end-use parts. This material is available on IN3DTEC online 3D printing store.

- ABS-M30i: ABS M30i is a high-performance, FDA-compliant thermoplastic material designed for 3D printing applications, particularly in industries where safety, durability, and regulatory compliance are critical. It is a variant of the standard ABS (Acrylonitrile Butadiene Styrene) material, engineered to meet the stringent requirements of the medical, food, and pharmaceutical industries. This material is available on IN3DTEC online 3D printing store.

- PPSU: PPSU (Polyphenylsulfone)is a high-performance, thermoplastic polymer known for its exceptional thermal stability, chemical resistance, biodegradable, and mechanical strength. It is a member of the sulfone polymer family, making it particularly suitable for demanding applications in industries that require high-performance materials. PPSU combines excellent mechanical properties with resistance to harsh chemicals, extreme temperatures, and stress. This material is available on IN3DTEC online 3D printing store.

Advantages of Biodegradable 3D Printing Materials

– Reduced Environmental Impact: By using materials that decompose naturally, we can significantly lessen the amount of plastic waste in landfills and oceans.

– Renewable Resources: Many biodegradable materials are derived from renewable resources, promoting a circular economy.

– Versatility: Biodegradable materials can be used in a variety of applications, from prototyping to creating products for consumer use.

Biodegradable 3D Printing Services

As demand for sustainable solutions grows, many companies are offering specialized services in biodegradable 3D printing. These services often include:

– Custom Design and Prototyping: Many businesses now provide the option to design and prototype using biodegradable materials, allowing for environmentally conscious product development.

– Educational Workshops: Some companies offer workshops to educate individuals and businesses about the benefits of sustainable practices in 3D printing.

– Recycling Programs: Certain services even incorporate recycling programs for used biodegradable materials, ensuring they are disposed of responsibly.

Real-World Applications

Biodegradable 3D printing materials are making waves in various fields:

– Medical Devices: Biodegradable materials can be used to create temporary implants or scaffolds that naturally dissolve in the body, reducing the need for additional surgeries.

– Packaging: Companies are exploring biodegradable 3D printed packaging solutions that are both functional and environmentally friendly.

– Consumer Products: From toys to household items, the use of biodegradable materials in consumer goods is on the rise, appealing to eco-conscious consumers.

The Future of Biodegradable 3D Printing

As technology advances and more research is conducted, the potential for biodegradable 3D printing materials is immense. Innovations in material science may lead to even more effective and versatile options, catering to a wider range of applications. Additionally, increased awareness and demand for sustainable practices will likely drive more businesses to adopt biodegradable solutions.

Conclusion

Biodegradable 3D printing materials and services represent a significant step towards a more sustainable future. By choosing eco-friendly options, we can reduce waste, promote renewable resources, and encourage responsible manufacturing practices. As we continue to innovate and explore new solutions, the possibilities for biodegradable 3D printing are endless. Embracing this technology not only benefits our planet but also paves the way for a greener tomorrow.

The post Sustainable Solutions: Biodegradable 3D Printing Materials and Services appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post What to Consider When Selecting a Metal 3D Printing Service appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>What to Consider When Selecting a Metal 3D Printing Service

Metal 3D printing, also known as additive manufacturing, is revolutionizing industries by enabling the production of complex and precise metal parts. Whether you’re creating functional prototypes, custom tools, or end-use components, choosing the right metal 3D printing service is critical to achieving high-quality results.

With various service providers and technologies available, how do you make the best choice? In this blog, we’ll explore the key factors to consider when selecting a metal 3D printing service.

1. Material Availability

The choice of material significantly impacts the performance and durability of your part. Common materials used in metal 3D printing include:

Stainless Steel: Corrosion-resistant and ideal for mechanical parts.In 3D printing, common stainless steel grades include 316L and 17-4 PH.

Aluminum: Lightweight and excellent for aerospace or automotive applications.With IN3DTEC, both AlSi10Mg and AL6061 are available, the last one also support anodizing surface finish.

Titanium(TC4, Grade 5): Strong and biocompatible, suitable for medical and aerospace industries.

Inconel 718&625 are available: Heat-resistant for applications in extreme environments like gas turbines.

Tool Steels: For high-strength tooling and manufacturing components.

Ensure the service provider offers the specific material you need for your project. Additionally, verify the material’s certification, especially for industries with strict quality standards like aerospace and healthcare. More technical information, please click here to download the TDS of each material.

2. Printing Technology

Different metal 3D printing technologies offer distinct advantages and limitations:

- Direct Metal Laser Sintering (DMLS) / Selective Laser Melting (SLM): High precision and density, ideal for complex geometries and functional parts.

- Binder Jetting: Cost-effective for large-scale production but may require post-processing for strength.

- Electron Beam Melting (EBM): Excellent for high-performance materials like titanium, commonly used in medical and aerospace fields.

- Metal Fused Deposition Modeling (FDM): A budget-friendly option for prototypes or non-critical applications.

Choose a service that uses the technology best suited to your application’s requirements.

More article: Different types of Metal 3D Printing technology

3. Part Size and Build Volume

Metal 3D printers have specific build volumes, which dictate the maximum size of parts they can produce. If your part exceeds the build volume, it may need to be printed in sections and assembled later, which could affect strength and aesthetics.

Verify that the service provider’s equipment can accommodate your design dimensions and inquire about their approach to larger or complex builds.

At IN3DTEC, the Max Build volume for metals is 500x500x500mm.

Upload your CAD files to the online quoting system to get an instant quote.

4. Quality Assurance and Certifications

Quality is paramount in metal 3D printing, particularly for applications in industries like aerospace, medical, and automotive. Look for 3D Printing service providers with inspection processes, such penetration testing, X-ray CT scanning or nondestructive testing, 3D Scanning & data matching to ensure part integrity.

5. Surface Finish and Post-Processing Options

Metal 3D printed parts often require post-processing to achieve the desired surface finish, strength, or functionality. Common post-processing techniques include:

- Heat Treatment: Enhances material properties like strength and ductility.

- CNC Machining: Improves dimensional accuracy and surface finish.

- Polishing: Achieves a smooth, aesthetic finish.

- Coatings: Adds corrosion resistance or improves wear resistance.

Ensure the service provider offers the post-processing options your project requires and understands how these processes integrate with their 3D printing workflow.

6. Lead Time and Production Speed

Time is often a critical factor in manufacturing projects. Ask about the 3D Printing service provider’s lead times, including both printing and post-processing phases.

- Prototyping: Some providers offer rapid turnaround for prototypes.

- Production: Ensure they can handle the scale of your production needs without delays.

A reliable service provider will have streamlined processes and clear communication to meet your deadlines.

7. Cost and Budget

Metal 3D printing can be costly, so it’s crucial to find the right balance between cost and quality. IN3DTEC is a leading provider of metal 3D printing services, offering high-quality prints at very competitive prices, with a fast turnaround time of as little as three days.

8. Design Expertise and Support

Metal 3D printing often requires design adjustments for manufacturability. Look for a service provider with experienced engineers who can:

- Optimize your design for additive manufacturing (e.g., reducing support structures, improving thermal flow).

- Provide feedback to ensure your part meets its functional requirements.

A collaborative approach can save time and resources while ensuring a successful outcome. Learn how to design parts for metals.

9. Reputation and Reviews

Research the service provider’s track record:

- Look for customer testimonials and case studies.

- Ask for samples of their previous work to evaluate quality.

- Consider their experience in your specific industry.

A reputable provider will have a proven history of delivering high-quality parts and excellent customer service.

10. Scalability

If you anticipate scaling production in the future, ensure the provider can handle increased demand without compromising quality or lead time. Services with multiple printers and robust workflows are better equipped for scalability. IN3DTEC has more than 80 units of industrial metal 3D Printers in-house.

Conclusion

Selecting the right metal 3D printing service is crucial for ensuring the success of your project. By considering factors such as material options, technology, quality assurance, and cost, you can make an informed decision that meets your technical and business needs.

Metal 3D printing is a powerful tool for producing innovative, high-performance parts. With the right service provider, you’ll unlock the full potential of this transformative technology.

The post What to Consider When Selecting a Metal 3D Printing Service appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post How to Export Your CAD Files for a Smoother Surface Finish appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>How to Export Your CAD Files for a Smoother Surface Finish

In the world of 3D printing and manufacturing, the quality of your final product is heavily influenced by how you export your CAD files. A smooth surface finish can enhance aesthetics, improve functionality, and reduce post-processing work. In this blog, we’ll explore techniques and tips for exporting CAD files to achieve a smoother surface finish.

Understanding Surface Finish in CAD

Before diving into the export process, it’s essential to understand what constitutes a “smooth” surface finish. Surface finish refers to the texture of a surface and is critical in applications where appearance and functionality matter. Common factors affecting surface finish include:

– Mesh Density: A higher density mesh can capture more details but may also lead to larger file sizes.

– Surface Normals: Correct orientation of surface normals ensures proper rendering and printing.

– File Format: Different formats can retain or lose information regarding surface quality.

Steps to Export CAD Files for a Smoother Surface Finish

- Optimize Your CAD Model

– Simplify Geometry: Remove unnecessary details that do not contribute to the final design. Complex geometry can lead to a more complicated mesh during export.

– Use Fillets and Chamfers: Adding fillets and chamfers can help smooth out edges and corners, which can improve the overall surface finish.

- Check Mesh Quality

– Analyze the Mesh: Use built-in tools in your CAD software to analyze the mesh quality. Look for issues like non-manifold edges or flipped normals.

– Repair the Mesh: Many CAD programs offer repair tools that can automatically fix common mesh issues, ensuring a smoother export.

- Choose the Right File Format

Different file formats have varying capabilities in preserving surface quality. Here are some common formats and their advantages:

– STL: Widely used for 3D printing, but it approximates surfaces as triangles, which can lead to a rough finish if not sufficiently detailed.

– OBJ:For low resolution of STL files, Try to export your STL files into OBJ format by using blender. Or import it in 3Dsmax and converted it to the highest resolution polymesh. Then decimated it in Zbrush. OBJ also Supports vertex colors and texture maps, making it a good choice for applications where appearance matters.

– STEP or IGES: These formats retain more geometric information and are ideal for engineering applications. Low precision issues that occur in STL files can often be resolved by exporting them as STP format.

- Adjust Export Settings

– Increase Resolution: If your software allows, increase the resolution of the mesh during export. This can help capture finer details, leading to a smoother surface.

– Check Normal Orientation: Ensure that the surface normals are facing outward, as inverted normals can cause rendering issues.

- Post-Processing Techniques

– Smoothing Algorithms: After exporting, consider using software like Meshmixer or Blender to apply smoothing algorithms. These tools can significantly enhance the surface quality of your model.

– Decimation:If the file size is a concern, use decimation techniques to reduce the number of polygons while retaining the smoothness of the surface.

- Test and Iterate

– Print Test Models: Conduct small test prints to evaluate surface finish. This will help you identify any issues before moving on to larger projects. Feel free to upload it to this website to view the surface, and this tool can help you find the thin thickness risk as well.

– Gather Feedback: If possible, share your models with peers or professionals to get feedback on the surface finish and make necessary adjustments.

Conclusion

Exporting your CAD files for a smoother surface finish is a combination of careful modeling, choosing the right file format, and utilizing the right settings during export. By following these steps, you can improve the quality of your designs, leading to better results in your final products. Whether you’re preparing for 3D printing or traditional manufacturing, investing time in the export process will pay off in the long run.

The post How to Export Your CAD Files for a Smoother Surface Finish appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post Top Free Tools for Repairing STL Files in 3D Printing appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>Top Free Tools for Repairing STL Files in 3D Printing

3D printing has revolutionized the way we create objects, but it’s not without its challenges. One common issue that many enthusiasts face is dealing with corrupted or flawed STL files. Fortunately, there are several free tools available that can help you repair these files and ensure a successful print. In this blog, we’ll explore some of the most popular options.

Overview:

Meshmixer is a powerful tool developed by Autodesk that allows users to manipulate 3D meshes easily. It includes a robust repair function that can fix various issues with STL files.

Key Features:

– Automatic mesh repair: Just load your STL file, and Meshmixer will analyze and fix it.

– Advanced editing tools: You can modify your model before printing, including scaling, rotating, and combining meshes.

How to Use:

- Import your STL file into Meshmixer.

- Select the “Analysis” menu and choose “Inspector.”

- Fix any highlighted issues, then export the repaired model.

Overview:

Netfabb Basic is a free version of Autodesk’s Netfabb software, specifically designed for 3D printing. It offers tools to repair and prepare STL files for printing.

Key Features:

– STL repair functions: Automatically identifies and fixes common issues.

– Orientation tools: Helps you position your model for optimal printing.

How to Use:

- Open your STL file in Netfabb Basic.

- Use the “Repair” tool to fix any errors.

- Save the repaired file for printing.

Overview:

Microsoft 3D Builder is a user-friendly application that comes pre-installed on Windows 10. It provides a simple way to view and repair STL files.

Key Features:

– Easy-to-use interface: Perfect for beginners who want a straightforward solution.

– Automatic repair options: Quickly fix common mesh problems.

How to Use:

- Open 3D Builder and import your STL file.

- Use the “Repair” function to identify and fix issues.

- Save your repaired file for 3D printing.

Overview:

Blender is a versatile open-source 3D modeling software that includes tools for repairing and editing STL files. While it has a steeper learning curve, it’s incredibly powerful for those willing to invest the time.

Key Features:

– Extensive editing capabilities: Modify your mesh in various ways beyond simple repairs.

– Community support: A vast number of tutorials available online.

How to Use:

- Import your STL file into Blender.

- Enter Edit Mode to inspect and fix mesh issues manually.

- Export the repaired file as an STL for printing.

Overview:

Sculptris is a free 3D sculpting tool that allows for easy manipulation of models. While primarily focused on sculpting, it also offers basic mesh repair capabilities.

Key Features:

– Intuitive interface: Great for beginners and those focused on artistic creation.

– Basic repair functions: Identify and fix mesh errors before printing.

How to Use:

- Open your STL file in Sculptris.

- Use the tools available to smooth and repair your model.

- Export the final version for printing.

Some 3d printing slicing software, such as PrusaSlicer and Bambustudio, also do simple repair work.

Conclusion

Repairing STL files is a crucial step in the 3D printing process. By utilizing these free tools, you can enhance your 3D modeling workflow and reduce the risk of print failures. Whether you prefer a straightforward approach with Meshmixer or need the advanced capabilities of Blender, there’s a tool out there that fits your needs. Happy printing!

The post Top Free Tools for Repairing STL Files in 3D Printing appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post Can You Electroplate 3D Prints? A Guide to Metallic Finishes appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>Can You Electroplate 3D Prints? A Guide to Metallic Finishes

In the world of 3D printing, innovation knows no bounds. While 3D printing allows for intricate designs and rapid prototyping, the surface finish of these prints often lacks the professional aesthetic or durability required for certain applications. Enter electroplating — a game-changing technique that can turn your 3D prints into stunning, metallic masterpieces. But how does it work, and is it the right choice for your project? Let’s dive in.

What is Electroplating?

Electroplating is a process where a thin layer of metal is deposited onto a substrate (in this case, a 3D-printed part) using an electrical current. The result is a shiny, durable, and metallic surface that enhances the appearance, strength, and conductivity of the original object.

This technique is widely used in manufacturing for creating jewelry, decorative finishes, and functional coatings. In the context of 3D printing, electroplating transforms lightweight plastic parts into objects with a professional, metallic finish.

Why Electroplate 3D Prints?

Electroplating offers several benefits:

- Enhanced Durability: Adds a layer of protection against wear and tear.

- Improved Aesthetics: Creates a polished, professional metallic look.

- Increased Strength: Strengthens the surface of lightweight plastic prints.

- Electrical Conductivity: Makes non-conductive materials conductive, useful in electronics.

Whether you’re creating a prototype, a decorative piece, or a functional part, electroplating can add value to your 3D-printed creations.

Can All 3D Prints Be Electroplated?

Not all 3D prints are suitable for electroplating. The substrate must typically be conductive to allow the process to work. However, most 3D-printed materials, like PLA, ABS, and resin, are non-conductive by nature. Here’s how to address this:

Surface Preparation:

Smooth the print by sanding or polishing to remove any imperfections. A smooth surface ensures an even electroplating finish.

Conductive Coating:

Apply a conductive paint or primer to the surface. This coating allows the electrical current to pass through during the plating process.

Material Selection:

While most materials can be prepared for electroplating, those with higher heat resistance (like ABS) are better suited to the preparatory processes.

How to Electroplate a 3D Print

Here’s a simplified step-by-step process:

Prepare the Surface:

Clean, sand, and polish your 3D print to remove any irregularities.

Apply Conductive Coating:

Spray or brush on a layer of conductive paint. Let it dry completely.

Set Up the Electroplating Bath:

Use a solution specific to the type of metal you want to plate (e.g., nickel, copper, or gold).

Attach an Electrode:

Connect your 3D print (now conductive) to the negative terminal of a power source and immerse it in the solution.

Plate the Metal:

Turn on the power and let the plating process occur. The metal ions in the solution will deposit onto your print.

Rinse and Polish:

After plating, rinse the part in water and polish it to achieve the desired finish.

Tips for Best Results

- Avoid Overplating: Too thick a metal layer can lead to cracking or distortion.

- Mind the Design: Sharp corners or intricate details may need extra care to ensure uniform plating.

- Test First: If you’re new to electroplating, practice on test pieces before working on your final design.

Applications of Electroplated 3D Prints

Electroplated 3D prints are ideal for:

- Decorative Pieces: Jewelry, trophies, and ornamental items.

- Functional Components: Conductive parts in electronics or durable prototypes.

- Display Models: Museum-quality replicas or architectural models.

Challenges to Consider

While electroplating is versatile, it comes with challenges:

- Cost: Metal solutions and conductive coatings can add to project costs.

- Skill Requirement: Proper setup and technique are critical for successful results.

- Material Limitations: Some materials are less compatible with the process.

Conclusion

Electroplating is a powerful way to elevate your 3D prints, offering both aesthetic and functional benefits. By combining the flexibility of 3D printing with the durability and shine of metal, you can create objects that are both innovative and visually stunning.

So, can you electroplate 3D prints? Absolutely! With the right preparation and tools, your plastic creations can rival traditional metal products in beauty and functionality.

Further Reading

Electroplating-vs-physical-vapor-deposition-pvd-coating-a-comparative-analysis

The post Can You Electroplate 3D Prints? A Guide to Metallic Finishes appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post 100 Cool & Useful Things, ideas to 3D Print for November 2024 appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>100 cool & useful 3D Print Projects, Ideas You’ll Love

In the ever-evolving world of technology, 3D printing stands out as a game-changing tool that empowers creators, hobbyists, and visionaries alike. Whether you’re a seasoned maker or just exploring the incredible world of additive manufacturing, the possibilities are practically endless. From practical gadgets to playful art pieces, 3D printing brings your ideas to life in tangible, creative ways.

In this blog, we’ve curated a list of 100 cool 3D print projects to fuel your creativity and spark your imagination. Each project is chosen for its uniqueness, functionality, or pure fun factor. So, fire up your 3D printer, and let’s dive into the thrilling world of cool 3D prints together!

Clik the Image to download the file

-

3D BENCHY 1

3D BENCHY 1CreativeTools 3DBenchy is a 3D model specifically designed for testing and benchmarking 3D printers.

-

Threaded Dragon Egg 2

Threaded Dragon Egg 2It's a threaded dragon egg, great for Easter egg hunts, gifts, and Game of Thrones fans.

-

Low Poly Howling Wolf 2.0 3

Low Poly Howling Wolf 2.0 3Low Poly Howling Wolf. Print Your Pack!! Great for Testing Input Shaping!!

-

DUMMY 13 Printable Jointed Figure (BETA FILES) 4

DUMMY 13 Printable Jointed Figure (BETA FILES) 4Another new addition to the Lucky 13 family

-

Stackable beer crate 5

Stackable beer crate 5Customizable (for CAD owners) & stackable beer crate for batteries

-

Rugged Box (Parametric) 6

Rugged Box (Parametric) 6Fully parameterized rugged tool box

-

Joycon Controller with Trigger buttons. 7

Joycon Controller with Trigger buttons. 73D ergonomic controller for Nintendo switch Joycons left and right.

-

Headphone stand 8

Headphone stand 8Headphone stand

-

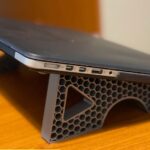

Laptop Stand 9

Laptop Stand 9Laptop stand, a simple and ergonomic stand, perfect for a laptop 13" or 15".

-

Phone/Tablet Stand 10

Phone/Tablet Stand 10This phone/tablet stand is designed to be as universal as possible, print in place, and fold flat while being very…

-

Deadpool Bust 11

Deadpool Bust 11Fan art sculpt of Deadpool. Thanks for printing!

-

Darth Vader Bust 12

Darth Vader Bust 12Cool Art of Dart Vader Bust

-

Low-Poly Snorlax 13

Low-Poly Snorlax 13Easy-to-print Snorlax design. No support material needed

-

Spiral Vase Rose 14

Spiral Vase Rose 14A rose designed to print in spiral vase mode.

-

Valentine Rose of Love 15

Valentine Rose of Love 15For your Valentine's Day

-

Collapsing Katana 16

Collapsing Katana 16This is a collapsing Katana sword designed to be printed as one part. Its only 182mm high when printed but expands to over 825mm in total length!

-

Vaporeon - Pokemon - Fan Art 17

Vaporeon - Pokemon - Fan Art 17 -

Snow Globe Votive Ornament - Winter Cabin 18

Snow Globe Votive Ornament - Winter Cabin 18Snow Globe Votive Ornament - Winter Cabin Insert an LED tea light candle (<38mm dia) in the base to light up the cabin.

-

Adjustable leg furniture 19

Adjustable leg furniture 19Adjustable leg for furniture

-

Dremel bit holder 20

Dremel bit holder 2060 bit holes Circular container: 45mm in diameter Squared container: 64mm x 45mm Total size: 120mm x 120mm x 15mm

-

Above Desk Drawer 21

Above Desk Drawer 21You must REALLY hate all that extra filament laying around to be looking at these.. The chassis take about a kg to print, and the drawers, feet, and hats take another like 600g.

-

Soft Tape Measure Spool 22

Soft Tape Measure Spool 22Soft Tape Measure Spool for a 5/8" wide, 5ft long soft tape measure. Super glue end of pin into core.

-

Toy Shooter 23

Toy Shooter 23This is a cartoon-style toy shooter, without firing capability and cannot be modified, making it safe to play. It features intricate design that allows for functions such as blowback shell ejecting action, locking the slide back on an empty magazine, trigger-hammer interaction, and a safety mechanism.

-

Cute Mini Octopus 24

Cute Mini Octopus 24Cute Mini Octopus, the original! It's designed so it can be printed at once. No assembly or supports required.

-

Engine Model 005 25

Engine Model 005 25This is a V-twin engine model that consists of various parts like a crankshaft, connecting rods, camshafts, gears, and a throttle valve, among others. It can replicate the functioning of a real engine.

-

SVS NASA Moon Globe 26

SVS NASA Moon Globe 26This has an 80mm opening on the base to set on a 10cm LED lighted puck.

-

Catch All Desk Organizer 27

Catch All Desk Organizer 27I couldn't find a tool organizer for my print station that met my exact needs so I said “to hell with it” and made my own...

-

Phone Stand 28

Phone Stand 28The stand is designed to hold the phone with or without a case. Accents on the side are printed separately and fitted in after being printed.

-

Foldable Book or Tablet Stand 29

Foldable Book or Tablet Stand 29Rest your book or tablet on this convenient stand, allowing you to keep your hands free while cooking, working, or studying.

-

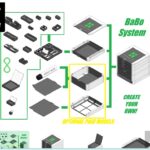

organizer drawer module 30 30

organizer drawer module 30 30This is the BaBo drawer module 30. The drawer module is the heart of the system as it carries the inserts and is therefore the main page of the system.

-

Portable Cable Organizer / Winder 31

Portable Cable Organizer / Winder 31A portable cable organizer which is setup as an easy print-in-place and includes a knob on the side for conveniently winding up the cable when you're ready to pack it away.

-

Flexi Toothless Dragon 32

Flexi Toothless Dragon 32No Supports necessary!

-

Organizer Box / Boxes 33

Organizer Box / Boxes 33The model is designed so that all punch holes are auto-calculated and evenly spaced. No need to fiddle around with manual settings, just define the basic parameters and watch the magic math

.

. -

3D Printable Jet Engine 34

3D Printable Jet Engine 34I have incorporated several minor design improvements to the parts to improve clearances, ease of printing, and ease of assembly.

-

Snowflake Coasters - Hueforge 35

Snowflake Coasters - Hueforge 35Cool flowers with easy print

-

Articulated Skeleton Dragon 36

Articulated Skeleton Dragon 36It's a fun piece of toy that's incredibly flexible, with virtually all joints capable of movement. It has become a huge hit with the kids at home!

-

Under Desk Drawers 37

Under Desk Drawers 37Got some filament to burn? Drawers made to be bolted/ hot glued/ double stick taped to the bottom of a desk or table

-

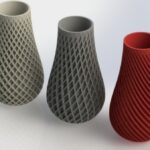

Spiral Vase 38

Spiral Vase 38For Home.

-

Faceted Chess Set 39

Faceted Chess Set 39Lorem ipsum dolor sit amet consectetur adipiscing elit dolor

-

PUSHER FOR TUBE PASTE 40

PUSHER FOR TUBE PASTE 40Simple & easy to use

-

Makeup Organizer Box 41

Makeup Organizer Box 41I created a 3D model of a Chinese product. Made on the eye, maybe someone will be useful. The dimensions are visible in the photo. If you want to change the size email me or edit SolidWorks file(which I also had).

-

Cable Clip 42

Cable Clip 42Had a couple of USB cables lying around so I decided to design a simple cable clip. The wire tension itself together with the curved back holds the cable in place.

-

Egg Separator (Kitchen) 43

Egg Separator (Kitchen) 43Simple Egg Separator that attaches to the side of your bowl. !Note: V3 Wide is for thicker bowls up to 10mm Safe 3D printing materials for food contact (FDA approved) can be found from IN3DTEC online 3D printing store

-

Made with Love Bokeh Kit 44

Made with Love Bokeh Kit 44Slick style meets practical engineering. Our Photography Gear puts the fun in functional with good-looking gear that streamlines your workflow and fuels your creativity.

-

Super Mario World Nintendo Switch Controller Pro Joy Con Wall Holder 45

Super Mario World Nintendo Switch Controller Pro Joy Con Wall Holder 45I have some Switch Pro Controller but didn't found holder for the wall I liked. So I got the idea to do a holder as a brick block with different designs. Then I thought, why not doing a complete wall with all your Switch stuff. And so here we go. I did a complete Super Mario World with holders for everything for the Switch.

-

Controller Mount (Switch/Xbox/PS4/+) 46

Controller Mount (Switch/Xbox/PS4/+) 46Minimalistic design meant to function for most all controller types. Requires no support material and prints in one quick and easy model. Includes both a narrow and wide version. In testing various controllers, some secured a bit nicer to a narrow version. Though the Wide version is the one pictured in the post print images.

-

Cable Gland for Desktop Sit-Up 47

Cable Gland for Desktop Sit-Up 47This two-piece cable gland is fixed with double-sided foam or a screw. I designed it as part of the realization of a motorized sitting/standing desk.

-

Petite Paint Palette 48

Petite Paint Palette 48This petite paint palette was thrown together when I ran out of 3D rubble to use as a palette. Designed to shorten the distance between paint and a held item, it has worked great for all my acrylic mini painting. It’s a quick print that speeds up painting, so I had share.

-

Modular holder for miniature paints and brushes 49

Modular holder for miniature paints and brushes 49In the pictures, you can see examples of the components printed as usual, or -- simply to make it all look a bit more interesting -- with no top and bottom layers. To get the honeycomb pattern, you can print with IN3DTEC use 20% honeycomb infill.

-

Watercolor Palette 50

Watercolor Palette 50Release your inner artist with this perfectly-portioned palette, designed for watercolors but useful for other paints as well. Simply add color, swirl your brush, and start your next masterpiece.

-

Strong Arm Hook 51

Strong Arm Hook 51Strong hook with one screw holes. Height - 54 mm Width - 30 mm Depth - 30mm Holes dia 4mm

-

Just eyes for Owl - wall key holder 52

Just eyes for Owl - wall key holder 52Cool design to place your keys at home.

-

Funny Cartoon Christmas Candle ( no 4 of 4) 53

Funny Cartoon Christmas Candle ( no 4 of 4) 53Cartoon-Style Christmas 3D print Candles, that you can use for your christmas decorations!

-

Striped Tea Candle Holder 54

Striped Tea Candle Holder 54Cool 3D Print candle for Christmas!

-

Tealight holder 55

Tealight holder 55This is a small but elegant 3D Print tealight holder.

-

Multi-Color Flying Helicopter Toy 56

Multi-Color Flying Helicopter Toy 56Multi-Color 3D Print Flying Helicopter Toy. Ideal for Children and education. For Fun.

-

PRINT-IN-PLACE PHONE HOLDER 57

PRINT-IN-PLACE PHONE HOLDER 57It is a cool Fully 3D-Printed Phone Holder for your desk, car or Space station

-

Mechanical Quick Grab/Release Phone Stand 58

Mechanical Quick Grab/Release Phone Stand 58This 3D Print stand allows multiple viewing angles and best of all has a quick grab/release mechanism that grabs and locks the phone in when you let go and releases when you pick up the phone.

-

2016 Suzuki GSX-RR 1:8 Racing RC MotoGP Version 2 59

2016 Suzuki GSX-RR 1:8 Racing RC MotoGP Version 2 59This 1/8 size Racing Motorcycle is far more advanced and has been completely redesigned with knowledge gained from actual RC motorcycle designers and racing enthusiasts whose invaluable input was incorporated into the design. This is not meant to be a good 3d printed RC motorcycle, but a serious new RC Motorcycle variant that people can build, design and race at the track.

-

Harley Davidson - Custom Fat Boy Style 60

Harley Davidson - Custom Fat Boy Style 60Harley Davidson - Custom Fat Boy Style - Scale 1:12 Fully printable model kit Spinning wheels Functional steering The design is divided in many different parts in order to allow printing different parts with different color This model does not need any additional non-3dprinted parts

-

Christmas Grogu 61

Christmas Grogu 61Supports needed for the cup and the edge of his sleeves. Pre-Supported .lys and .stl files for resin included

-

Collapsing Master Sword with Replaceable Blade 62

Collapsing Master Sword with Replaceable Blade 62Unlike the 3D Print-N-Place version, the pommel on the hilt of this Master Sword is threaded which allows the blade to be printed separately and inserted. The assembled hilt is 250mm long but the blade extends to a length of 870mm long in total!

-

3D Printed Exoskeleton Hands 63

3D Printed Exoskeleton Hands 633D printed exoskeleton hands that I made for a bit of fun.

-

Starcraft Marines 64

Starcraft Marines 64Starcraft fanart. 3 Marine models.

-

Genji Fan Art 65

Genji Fan Art 65Comes with Supported and Unsupported stl. Base made to 3d print lying flat, with supported underbelly.

-

3D Printed one hand book holder 66

3D Printed one hand book holder 66This object will simplify your life, allowing you to read your books with one hand and without any thumb cramp !

-

Malte Fürstenberg 67

Malte Fürstenberg 67Bananaaaaaa, you will like this cool 3D print. It Can be 3D printed with IN3DTEC full color printing service.

-

"Hammered" Patrick! 68

"Hammered" Patrick! 68Inspired by Patrick Star, SpongeBob's best friend! Master of the art of doing nothing at all, Patrick is one of the funniest characters ever created! It Can be 3D printed with IN3DTEC full color printing service.

-

Ultra swole Pikachu 69

Ultra swole Pikachu 69Ultra swole Pikachu! I created this for fun. Sculpted in Zbrush, part separated and repaired with Maya and Meshmixer. Can be 3D printed with IN3DTEC full color printing service.

-

Baby Groot flower pot 70

Baby Groot flower pot 70Cool 3D prints and innovate creation

-

Lion Ring for comp 71

Lion Ring for comp 71Lorem ipsum dolor sit amet consectetur adipiscing elit dolor

-

Crocodile Ring 72

Crocodile Ring 72This design is ideal for 316L Steel 3D printing, with stone polishing. You can find this from IN3DTEC online quote system

-

Ring - Folded faces 73

Ring - Folded faces 73This design is ideal for 316L Steel 3D printing, with stone polishing. You can find this from IN3DTEC online quote system

-

Crow's Skull 74

Crow's Skull 74This design is ideal for 316L Steel 3D printing, with stone polishing. You can find this from IN3DTEC online quote system

-

Santa and Snowman - Christmas multicolor knitted container 75

Santa and Snowman - Christmas multicolor knitted container 75Santa is printed in 4 colors with 1 AMS unit. (the belt buckle was painted with yellow acrylic paint, if you have another AMS unit you can add the yellow color).

You can find multiple color printing servcie from IN3DTEC.

You can find multiple color printing servcie from IN3DTEC. -

![Stitch [Lilo and Stitch]](https://www.in3dtec.com/wp-content/uploads/2024/08/76-150x150.jpg) Stitch [Lilo and Stitch] 76

Stitch [Lilo and Stitch] 76Today we're bringing you a 3D printed Stitch from the Disney movie Lilo and Stitch. Stitch is such an iconic character, and it was really fun to make into a full figure.

-

Controller Mount (Switch/Xbox/PS4/+) - No supports/one piece 77

Controller Mount (Switch/Xbox/PS4/+) - No supports/one piece 77Minimalistic design meant to function for most all controller types. Requires no support material and prints in one quick and easy model. Includes both a narrow and wide version. In testing various controllers, some secured a bit nicer to a narrow version. Though the Wide version is the one pictured in the post print images.

-

Smaller Print-in-place Massage Roller 78

Smaller Print-in-place Massage Roller 78Ideal for body massage, you can select IN3DTEC printing service for customized colors.

-

Cable holder 79

Cable holder 79Summary USB cable holder.

-

Dummy 13 - version 1.0! 80

Dummy 13 - version 1.0! 80Dummy 13 is a 3D printable action figure designed for super expressive articulation and infinite customization, accessible to anyone with a 3D printer.

-

Wall hook 81

Wall hook 818 different wall hooks in different size and sturdiness.

-

Bath Glass Shower Hook 82

Bath Glass Shower Hook 82A hook for bathroom glass shower available in various glass thickness and width.

-

Fluffy Birds 83

Fluffy Birds 83Have you ever wished for a little companion to keep you company at your desk? Perhaps you’ve just found one! Here’s a fluffy little bird—a robin, but it doesn’t have a name yet. You can print it out and give it a name!

-

STomHacks 84

STomHacks 84No support required

-

Wireless Mouse 85

Wireless Mouse 85This 3D-printed mouse features a futuristic hollow shell design that showcases its internal structure. The generative design of the shell is something only achievable through 3D printing. Our industrial designers have fully harnessed the advantages of 3D-printed structures to bring you this stunningly crafted mouse.

-

Led Lamp 86

Led Lamp 86This LED lamp project offers two types of 3D printed lampshades. Type A features a hollow and angular design, while Type B showcases textured and wavy patterns. We recommend to select Translucent material by using FDM or SLA 3D printing from IN3DTEC 3D printing service.

-

Honeycomb Wall 87

Honeycomb Wall 87You can connect the basic parts of the wall together. You can connect it also with printable parts which can be used in various ways (you can use it for screwing to the wall, you can use it as a holder for hanger or as a holder for hook).

-

12-hole playable Ocarina 88

12-hole playable Ocarina 88As Gabriel_Knight pointed out, it might actually better to print this with the pointy end down, not up, as I initially thought.

-

Moon City 2.0 89

Moon City 2.0 89This is the latest (2.0) free version of my Moon City

-

TT violent tourbillon 90

TT violent tourbillon 90This is a 3D printed three-axis tourbillon model whose design is inspired by the tourbillon in the Jacob & Co. Twin Turbo Furious watch. A tourbillon is a mechanism used to counteract the effects of gravity within a watch. This sophisticated model includes an escape wheel, a three-axis frame and a base with integrated motor. It operates on the same principle as a traditional tourbillon watch.

-

V3 Series - Impossible Penetration Cone 91

V3 Series - Impossible Penetration Cone 91This is an updated version of the V3 Series Vortex Thread/Impossible Cone This version is slightly shorter in length, 72mm, and slightly wider, 42mm, and feels better than the original version. Clearances have been optimized and exterior details add to the appeal. NOTE: Cone dimensions are different than other V3 cones I have made

-

Infinite Cube 92

Infinite Cube 92Introducing the Infinity Rubik's Cube, a charming fusion of geometry and minimalism! Its 111 mm size brings a touch of modern elegance to any space. Whether it's a centerpiece on your desk, bookshelf or living room, it's more than decoration - it's an engaging conversation piece and a tribute to endless possibilities!

-

Cute lizard with movable joints 93

Cute lizard with movable joints 93This incredibly cute 3D printed lizard! It's more than just a model; it's a fun-filled project where you can assemble your own colorful friends.

-

Charming Dinosaur 94

Charming Dinosaur 94Introducing the most charming dinosaur you'll ever meet - the delightfully chubby and irresistibly adorable dino!

With its plump, soft design and fully movable joints, this little creature is not just a decoration; it’s a heartwarming companion that will bring joy to any space. Effortlessly easy to print and impossibly easy to love, this lovable dinosaur is an essential addition to your collection! Don’t miss out on the chance to brighten up your surroundings with its cheerful presence!

With its plump, soft design and fully movable joints, this little creature is not just a decoration; it’s a heartwarming companion that will bring joy to any space. Effortlessly easy to print and impossibly easy to love, this lovable dinosaur is an essential addition to your collection! Don’t miss out on the chance to brighten up your surroundings with its cheerful presence! -

Large building blocks * Captain Brick Beard * Pirate * 500% 95

Large building blocks * Captain Brick Beard * Pirate * 500% 95This model is designed for multiple color 3d printing.

-

Solar System Lithophane Planet Lamp Collection 96

Solar System Lithophane Planet Lamp Collection 96After more than two years of designing and prototyping, I am very happy to finally present you the Solar System Planet Lamp Collection. In the course of this, I printed over 50 lamp prototypes and spent more than 20 kg of Filament

-

BOX OPENER - TESTED 97

BOX OPENER - TESTED 97Easy to print - Easy to handle Perfect for openeing your boxes

-

Articulating Raccoon - No Supports 98

Articulating Raccoon - No Supports 98Here is the Raccoon Model! The multicolor and single-color files are included. Even if your slicer isn't compatible with the included 3mf file, the single-color file is designed to be easy to paint in your slicer of choice. Just simply use the fill tool in your slicer to paint the different colors. Enjoy!

-

CYBER CAT: UNIVERSAL HEADPHONE HOLDER 99

CYBER CAT: UNIVERSAL HEADPHONE HOLDER 99Let the Cyber Cat Bite Your Headphones! This is the Cyber Cat! A Universal Headphone Holder, with movable jaw and retractable teeth!

-

KNITTED SNOWMAN 100

KNITTED SNOWMAN 100This is a cute knitted Snowman same as your grandma would have knitted for you. This needs no supports to print. No assembly needed after print. Make sure to upload a make after printing. Thank You!

The post 100 Cool & Useful Things, ideas to 3D Print for November 2024 appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post Exploring the Fascinating World of Infill Patterns in 3D Printing appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>Exploring the Fascinating World of Infill Patterns in 3D Printing

3D printing has revolutionized the way we create objects, allowing us to transform digital designs into physical reality with remarkable precision and versatility. One of the crucial aspects that contribute to the strength, weight, and print time of 3D printed objects is the infill pattern. In this blog, we’ll delve into the fascinating world of infill patterns, exploring what they are, why they matter, and the various types available.

What is Infill in 3D Printing?

Infill refers to the internal structure of a 3D printed object. While the outer shell (or perimeter) of a print defines its shape, the infill is the internal lattice-like pattern that fills the space inside. This pattern not only impacts the object’s strength and weight but also affects the amount of material used and the overall printing time.

Why Does Infill Matter?

- Strength and Durability:Different infill patterns provide varying degrees of strength. For instance, a higher infill density (closer to 100%) will result in a stronger and more durable object, suitable for functional parts that need to withstand stress.

- Weight Reduction:Lower infill densities create lighter objects, which can be advantageous for applications where weight is a critical factor, such as in aerospace or automotive industries.

- Material Usage:Infill patterns can significantly reduce the amount of filament used, making the printing process more cost-effective and environmentally friendly.

- Print Time:More complex infill patterns and higher densities increase the print time. Balancing between strength, material usage, and print time is key to optimizing 3D printing projects.

Common Types of Infill Patterns

Rectilinear: This is the most basic and commonly used infill pattern. It consists of straight lines that create a grid-like structure. It is efficient and provides decent strength but may not be the best for complex or highly stressed parts.

P.S: In cura, it is called Zig Zag. In Simplify3d, Prusa slicer and bambu studio it is called Rectilinear

Honeycomb: Resembling a beehive’s structure, the honeycomb pattern is excellent for creating lightweight yet strong parts. Its hexagonal cells distribute stress evenly, making it ideal for functional components.

P.S: This pattern is valid on Simpify3d,Prusa Slicer & bambu studio, but invalid on Cura

Gyroid: Known for its unique and visually appealing 3D labyrinth-like structure, the gyroid infill offers excellent strength in multiple directions. It’s particularly useful for objects requiring a balance between strength and flexibility.

P.S: This pattern is valid on Cura,Prusa Slicer & bambu studio, but invalid on Simplify3d

Triangular: This pattern forms triangles within the infill, providing good strength and stability. It’s often used for parts that need to withstand compression forces.

P.S: This pattern is valid on all of Cura,Prusa Slicer & bambu studio, and simplify3d

Cubic: A pattern that creates a 3D grid of cubes. It provides uniform strength in all directions and is suitable for parts that need to handle multi-directional stress.

P.S: This pattern is valid on Cura,Prusa Slicer & bambu studio, but invalid on Simplify3d

Concentric: This infill pattern consists of concentric shapes (circles, squares, etc.) that follow the contour of the object. It’s great for parts that need to maintain strength around their perimeters.

P.S: This pattern is valid on Cura,Prusa Slicer & bambu studio, but invalid on Simplify3d

How to select a right 3d printing slicer? Read More

Choosing the Right Infill Pattern

The choice of infill pattern depends on the specific requirements of your project. Here are some tips to help you decide:

– Functional Parts: For parts that will endure significant stress or load, consider using honeycomb, gyroid, or cubic infill patterns.

– Aesthetic Models: If the object is purely for display, a lower density infill like rectilinear or concentric can save material and print time.

– Flexibility Needs: For objects that need some flexibility, gyroid or honeycomb patterns are good choices.

– Print Time and Material: If reducing print time and material usage is a priority, opt for simpler patterns like rectilinear or triangular with a lower infill density.

Conclusion

Infill patterns play a crucial role in 3D printing, influencing the strength, weight, material usage, and print time of printed objects. Understanding the various infill options and their applications can help you optimize your 3D printing projects for specific needs. Whether you’re creating a sturdy functional part or a lightweight prototype, selecting the right infill pattern is key to achieving the desired performance and efficiency.

The post Exploring the Fascinating World of Infill Patterns in 3D Printing appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>The post 100 Innovative 3D Print Projects You Will Love appeared first on IN3DTEC | Prototyping & On-demand manufacturing services.

]]>100 Innovative 3D Print Projects You’ll Love

Introduction

In the ever-evolving world of technology, 3D printing stands out as a revolutionary tool that empowers creators, hobbyists, and innovators alike. Whether you’re a seasoned maker or just dipping your toes into the fascinating realm of additive manufacturing, the possibilities are virtually limitless. From practical gadgets to whimsical art pieces, 3D printing allows you to transform your ideas into tangible reality.

In this blog, we’ve curated a list of 100 innovative 3D print projects that will inspire your creativity and spark your imagination. Each project has been selected for its uniqueness, practicality, or sheer fun factor. So, grab your 3D printer, and let’s explore the exciting world of 3D printing together!

Clik the Image to download the file

-

3D BENCHY 1

3D BENCHY 1CreativeTools 3DBenchy is a 3D model specifically designed for testing and benchmarking 3D printers.

-

Threaded Dragon Egg 2

Threaded Dragon Egg 2It's a threaded dragon egg, great for Easter egg hunts, gifts, and Game of Thrones fans.

-

Low Poly Howling Wolf 2.0 3

Low Poly Howling Wolf 2.0 3Low Poly Howling Wolf. Print Your Pack!! Great for Testing Input Shaping!!

-

DUMMY 13 Printable Jointed Figure (BETA FILES) 4

DUMMY 13 Printable Jointed Figure (BETA FILES) 4Another new addition to the Lucky 13 family

-

Stackable beer crate 5

Stackable beer crate 5Customizable (for CAD owners) & stackable beer crate for batteries

-

Rugged Box (Parametric) 6

Rugged Box (Parametric) 6Fully parameterized rugged tool box

-

Joycon Controller with Trigger buttons. 7

Joycon Controller with Trigger buttons. 73D ergonomic controller for Nintendo switch Joycons left and right.

-

Headphone stand 8

Headphone stand 8Headphone stand

-

Laptop Stand 9

Laptop Stand 9Laptop stand, a simple and ergonomic stand, perfect for a laptop 13" or 15".

-

Phone/Tablet Stand 10

Phone/Tablet Stand 10This phone/tablet stand is designed to be as universal as possible, print in place, and fold flat while being very…

-

Deadpool Bust 11

Deadpool Bust 11Fan art sculpt of Deadpool. Thanks for printing!

-

Darth Vader Bust 12

Darth Vader Bust 12Cool Art of Dart Vader Bust

-

Low-Poly Snorlax 13

Low-Poly Snorlax 13Easy-to-print Snorlax design. No support material needed

-

Spiral Vase Rose 14

Spiral Vase Rose 14A rose designed to print in spiral vase mode.

-

Valentine Rose of Love 15

Valentine Rose of Love 15For your Valentine's Day

-

Collapsing Katana 16

Collapsing Katana 16This is a collapsing Katana sword designed to be printed as one part. Its only 182mm high when printed but expands to over 825mm in total length!

-

Vaporeon - Pokemon - Fan Art 17

Vaporeon - Pokemon - Fan Art 17 -

Snow Globe Votive Ornament - Winter Cabin 18

Snow Globe Votive Ornament - Winter Cabin 18Snow Globe Votive Ornament - Winter Cabin Insert an LED tea light candle (<38mm dia) in the base to light up the cabin.

-

Adjustable leg furniture 19

Adjustable leg furniture 19Adjustable leg for furniture

-

Dremel bit holder 20

Dremel bit holder 2060 bit holes Circular container: 45mm in diameter Squared container: 64mm x 45mm Total size: 120mm x 120mm x 15mm

-

Above Desk Drawer 21

Above Desk Drawer 21You must REALLY hate all that extra filament laying around to be looking at these.. The chassis take about a kg to print, and the drawers, feet, and hats take another like 600g.

-

Soft Tape Measure Spool 22

Soft Tape Measure Spool 22Soft Tape Measure Spool for a 5/8" wide, 5ft long soft tape measure. Super glue end of pin into core.

-

Toy Shooter 23

Toy Shooter 23This is a cartoon-style toy shooter, without firing capability and cannot be modified, making it safe to play. It features intricate design that allows for functions such as blowback shell ejecting action, locking the slide back on an empty magazine, trigger-hammer interaction, and a safety mechanism.

-

Cute Mini Octopus 24

Cute Mini Octopus 24Cute Mini Octopus, the original! It's designed so it can be printed at once. No assembly or supports required.

-

Engine Model 005 25

Engine Model 005 25This is a V-twin engine model that consists of various parts like a crankshaft, connecting rods, camshafts, gears, and a throttle valve, among others. It can replicate the functioning of a real engine.

-

SVS NASA Moon Globe 26

SVS NASA Moon Globe 26This has an 80mm opening on the base to set on a 10cm LED lighted puck.

-

Catch All Desk Organizer 27

Catch All Desk Organizer 27I couldn't find a tool organizer for my print station that met my exact needs so I said “to hell with it” and made my own...

-

Phone Stand 28

Phone Stand 28The stand is designed to hold the phone with or without a case. Accents on the side are printed separately and fitted in after being printed.

-

Foldable Book or Tablet Stand 29

Foldable Book or Tablet Stand 29Rest your book or tablet on this convenient stand, allowing you to keep your hands free while cooking, working, or studying.

-

organizer drawer module 30 30

organizer drawer module 30 30This is the BaBo drawer module 30. The drawer module is the heart of the system as it carries the inserts and is therefore the main page of the system.

-

Portable Cable Organizer / Winder 31

Portable Cable Organizer / Winder 31A portable cable organizer which is setup as an easy print-in-place and includes a knob on the side for conveniently winding up the cable when you're ready to pack it away.

-

Flexi Toothless Dragon 32

Flexi Toothless Dragon 32No Supports necessary!

-

Organizer Box / Boxes 33

Organizer Box / Boxes 33The model is designed so that all punch holes are auto-calculated and evenly spaced. No need to fiddle around with manual settings, just define the basic parameters and watch the magic math

.

. -

3D Printable Jet Engine 34

3D Printable Jet Engine 34I have incorporated several minor design improvements to the parts to improve clearances, ease of printing, and ease of assembly.

-

Snowflake Coasters - Hueforge 35

Snowflake Coasters - Hueforge 35Cool flowers with easy print

-

Articulated Skeleton Dragon 36

Articulated Skeleton Dragon 36It's a fun piece of toy that's incredibly flexible, with virtually all joints capable of movement. It has become a huge hit with the kids at home!

-

Under Desk Drawers 37

Under Desk Drawers 37Got some filament to burn? Drawers made to be bolted/ hot glued/ double stick taped to the bottom of a desk or table

-

Spiral Vase 38

Spiral Vase 38For Home.

-

Faceted Chess Set 39

Faceted Chess Set 39Lorem ipsum dolor sit amet consectetur adipiscing elit dolor

-

PUSHER FOR TUBE PASTE 40

PUSHER FOR TUBE PASTE 40Simple & easy to use

-

Makeup Organizer Box 41

Makeup Organizer Box 41I created a 3D model of a Chinese product. Made on the eye, maybe someone will be useful. The dimensions are visible in the photo. If you want to change the size email me or edit SolidWorks file(which I also had).

-

Cable Clip 42

Cable Clip 42Had a couple of USB cables lying around so I decided to design a simple cable clip. The wire tension itself together with the curved back holds the cable in place.

-

Egg Separator (Kitchen) 43

Egg Separator (Kitchen) 43Simple Egg Separator that attaches to the side of your bowl. !Note: V3 Wide is for thicker bowls up to 10mm Safe 3D printing materials for food contact (FDA approved) can be found from IN3DTEC online 3D printing store

-

Made with Love Bokeh Kit 44

Made with Love Bokeh Kit 44Slick style meets practical engineering. Our Photography Gear puts the fun in functional with good-looking gear that streamlines your workflow and fuels your creativity.

-

Super Mario World Nintendo Switch Controller Pro Joy Con Wall Holder 45

Super Mario World Nintendo Switch Controller Pro Joy Con Wall Holder 45I have some Switch Pro Controller but didn't found holder for the wall I liked. So I got the idea to do a holder as a brick block with different designs. Then I thought, why not doing a complete wall with all your Switch stuff. And so here we go. I did a complete Super Mario World with holders for everything for the Switch.

-

Controller Mount (Switch/Xbox/PS4/+) 46

Controller Mount (Switch/Xbox/PS4/+) 46Minimalistic design meant to function for most all controller types. Requires no support material and prints in one quick and easy model. Includes both a narrow and wide version. In testing various controllers, some secured a bit nicer to a narrow version. Though the Wide version is the one pictured in the post print images.

-

Cable Gland for Desktop Sit-Up 47

Cable Gland for Desktop Sit-Up 47This two-piece cable gland is fixed with double-sided foam or a screw. I designed it as part of the realization of a motorized sitting/standing desk.

-

Petite Paint Palette 48

Petite Paint Palette 48This petite paint palette was thrown together when I ran out of 3D rubble to use as a palette. Designed to shorten the distance between paint and a held item, it has worked great for all my acrylic mini painting. It’s a quick print that speeds up painting, so I had share.

-

Modular holder for miniature paints and brushes 49

Modular holder for miniature paints and brushes 49In the pictures, you can see examples of the components printed as usual, or -- simply to make it all look a bit more interesting -- with no top and bottom layers. To get the honeycomb pattern, you can print with IN3DTEC use 20% honeycomb infill.

-

Watercolor Palette 50

Watercolor Palette 50Release your inner artist with this perfectly-portioned palette, designed for watercolors but useful for other paints as well. Simply add color, swirl your brush, and start your next masterpiece.

-

Strong Arm Hook 51

Strong Arm Hook 51Strong hook with one screw holes. Height - 54 mm Width - 30 mm Depth - 30mm Holes dia 4mm

-

Just eyes for Owl - wall key holder 52

Just eyes for Owl - wall key holder 52Cool design to place your keys at home.

-

Funny Cartoon Christmas Candle ( no 4 of 4) 53

Funny Cartoon Christmas Candle ( no 4 of 4) 53Cartoon-Style Christmas 3D print Candles, that you can use for your christmas decorations!

-

Striped Tea Candle Holder 54

Striped Tea Candle Holder 54Cool 3D Print candle for Christmas!

-

Tealight holder 55

Tealight holder 55This is a small but elegant 3D Print tealight holder.

-

Multi-Color Flying Helicopter Toy 56

Multi-Color Flying Helicopter Toy 56Multi-Color 3D Print Flying Helicopter Toy. Ideal for Children and education. For Fun.

-

PRINT-IN-PLACE PHONE HOLDER 57

PRINT-IN-PLACE PHONE HOLDER 57It is a cool Fully 3D-Printed Phone Holder for your desk, car or Space station

-

Mechanical Quick Grab/Release Phone Stand 58

Mechanical Quick Grab/Release Phone Stand 58This 3D Print stand allows multiple viewing angles and best of all has a quick grab/release mechanism that grabs and locks the phone in when you let go and releases when you pick up the phone.

-

2016 Suzuki GSX-RR 1:8 Racing RC MotoGP Version 2 59

2016 Suzuki GSX-RR 1:8 Racing RC MotoGP Version 2 59This 1/8 size Racing Motorcycle is far more advanced and has been completely redesigned with knowledge gained from actual RC motorcycle designers and racing enthusiasts whose invaluable input was incorporated into the design. This is not meant to be a good 3d printed RC motorcycle, but a serious new RC Motorcycle variant that people can build, design and race at the track.

-

Harley Davidson - Custom Fat Boy Style 60

Harley Davidson - Custom Fat Boy Style 60Harley Davidson - Custom Fat Boy Style - Scale 1:12 Fully printable model kit Spinning wheels Functional steering The design is divided in many different parts in order to allow printing different parts with different color This model does not need any additional non-3dprinted parts

-

Christmas Grogu 61

Christmas Grogu 61Supports needed for the cup and the edge of his sleeves. Pre-Supported .lys and .stl files for resin included

-

Collapsing Master Sword with Replaceable Blade 62

Collapsing Master Sword with Replaceable Blade 62Unlike the 3D Print-N-Place version, the pommel on the hilt of this Master Sword is threaded which allows the blade to be printed separately and inserted. The assembled hilt is 250mm long but the blade extends to a length of 870mm long in total!

-

3D Printed Exoskeleton Hands 63

3D Printed Exoskeleton Hands 633D printed exoskeleton hands that I made for a bit of fun.

-

Starcraft Marines 64

Starcraft Marines 64Starcraft fanart. 3 Marine models.

-

Genji Fan Art 65

Genji Fan Art 65Comes with Supported and Unsupported stl. Base made to 3d print lying flat, with supported underbelly.

-

3D Printed one hand book holder 66

3D Printed one hand book holder 66This object will simplify your life, allowing you to read your books with one hand and without any thumb cramp !

-

Malte Fürstenberg 67

Malte Fürstenberg 67Bananaaaaaa, you will like this cool 3D print. It Can be 3D printed with IN3DTEC full color printing service.

-

"Hammered" Patrick! 68

"Hammered" Patrick! 68Inspired by Patrick Star, SpongeBob's best friend! Master of the art of doing nothing at all, Patrick is one of the funniest characters ever created! It Can be 3D printed with IN3DTEC full color printing service.

-

Ultra swole Pikachu 69

Ultra swole Pikachu 69Ultra swole Pikachu! I created this for fun. Sculpted in Zbrush, part separated and repaired with Maya and Meshmixer. Can be 3D printed with IN3DTEC full color printing service.

-

Baby Groot flower pot 70

Baby Groot flower pot 70Cool 3D prints and innovate creation

-

Lion Ring for comp 71

Lion Ring for comp 71Lorem ipsum dolor sit amet consectetur adipiscing elit dolor

-

Crocodile Ring 72

Crocodile Ring 72This design is ideal for 316L Steel 3D printing, with stone polishing. You can find this from IN3DTEC online quote system

-

Ring - Folded faces 73

Ring - Folded faces 73This design is ideal for 316L Steel 3D printing, with stone polishing. You can find this from IN3DTEC online quote system

-

Crow's Skull 74

Crow's Skull 74This design is ideal for 316L Steel 3D printing, with stone polishing. You can find this from IN3DTEC online quote system

-

Santa and Snowman - Christmas multicolor knitted container 75

Santa and Snowman - Christmas multicolor knitted container 75Santa is printed in 4 colors with 1 AMS unit. (the belt buckle was painted with yellow acrylic paint, if you have another AMS unit you can add the yellow color).

You can find multiple color printing servcie from IN3DTEC.

You can find multiple color printing servcie from IN3DTEC. -

![Stitch [Lilo and Stitch]](https://www.in3dtec.com/wp-content/uploads/2024/08/76-150x150.jpg) Stitch [Lilo and Stitch] 76

Stitch [Lilo and Stitch] 76Today we're bringing you a 3D printed Stitch from the Disney movie Lilo and Stitch. Stitch is such an iconic character, and it was really fun to make into a full figure.

-

CONTROLLER MOUNT (SWITCH/XBOX/PS4/+) - NO SUPPORTS/ONE PIECE 77

CONTROLLER MOUNT (SWITCH/XBOX/PS4/+) - NO SUPPORTS/ONE PIECE 77Minimalistic design meant to function for most all controller types. Requires no support material and prints in one quick and easy model. Includes both a narrow and wide version. In testing various controllers, some secured a bit nicer to a narrow version. Though the Wide version is the one pictured in the post print images.

-

Smaller Print-in-place Massage Roller 78

Smaller Print-in-place Massage Roller 78Ideal for body massage, you can select IN3DTEC printing service for customized colors.

-

Cable holder 79

Cable holder 79Summary USB cable holder.

-

Dummy 13 - version 1.0! 80