3. Common Types of Injection Molding Gates

Injection molding gate design and selection depends on a variety of factors, including part geometry, material properties, production volumes, and aesthetic requirements. Depending on the specific needs of the part and molding process, different types of gates can be used, sprue gates, edge gates, submarine gates, pinpoint gates, and fan gates.

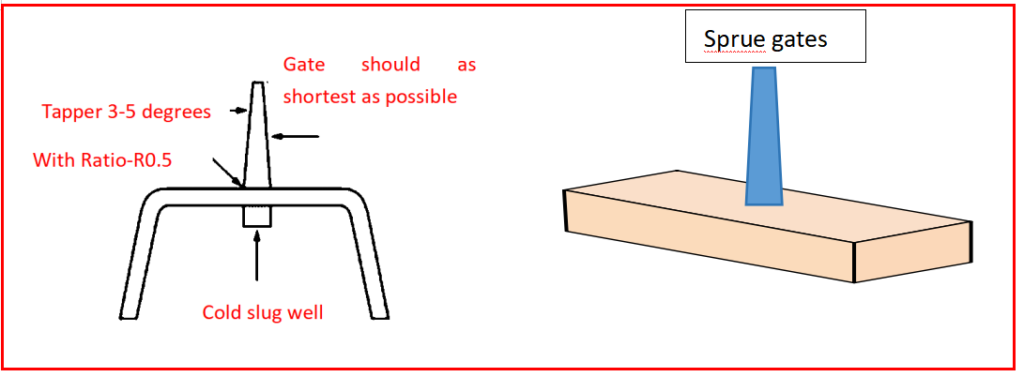

-Spure Gates:

Spure Gates are commonly used in injection molding. They consist of a conical opening located in the thickest part of the mold. Molten plastic flows directly into the mold cavity through the gate, ensuring even filling. After molding, the Sprue gate is separated from the final part. The Sprue gate is simple and the flow control is good, making it suitable for larger parts. However, they leave visible marks on the part and have limited placement options.

– Edge gates:

An edge gate is an injection molding gate located at the edge of a part. They provide controlled filling and minimize visible gate marks on the part surface. Edge gates offer design flexibility but are limited to specific gate locations.

– Submarine gates:

Submarine gates are hidden injection molding gates located beneath the surface of the part or in hidden areas. They provide excellent aesthetics, minimize visible gate marks, and are suitable for complex part geometries. Careful design and process analysis are necessary for successful implementation.

– Pinpoint gates:

Pinpoint also known as pinpoint or pinpoint edge gates, are a type of small and precise gating technique used in injection molding. These gates feature a tiny, pinpoint-sized opening through which molten plastic is injected into the mold cavity. They are typically located at the edge of the part or in a discreet area to minimize their visibility on the finished product.

Pinpoint gates offer several advantages, including reduced gate vestige, minimal part distortion, and improved surface finish. They allow for precise control over the flow of molten plastic, resulting in better part quality and reduced material waste. However, pinpoint gates may require careful design considerations and can be more susceptible to clogging due to their small size.

– Fan gates:

A fan gate is an injection molding gate with a triangular or fan-shaped opening. They evenly distribute the flow of plastic, improving part quality and aesthetics. However, they may leave visible gate marks on the part. Sector gates are often used in applications where balanced filling and appearance are important.

4. Factors to Consider When Choosing a Gate

The design and geometry of the part have a significant impact on gate selection. Consider the part’s size, shape, thickness, and any intricate features. Different gate types, such as sprue gates, edge gates, or submarine gates, may be more suitable depending on the part’s specific requirements.

Part Quality and Appearance:

The location and design of the gate affects the aesthetics and overall quality of the part. If gate markings need to be minimized or hidden, options such as edge gates or submarine gates may be preferred. On the other hand, if gate visibility is not an issue, a sprue gate or fan gate may be more suitable.

Flow Control:

Effective flow control is critical to ensuring proper filling of the mold cavity and minimizing defects. Consider gate size, shape and flow characteristics. Gates should be carefully sized to maintain the proper balance between flow, pressure and cooling.

Material Selection:

Different materials have unique flow characteristics and viscosity. Some materials require larger or smaller gates to achieve optimal flow. Consider the material’s melt temperature, viscosity, and any specific processing requirements when selecting the gate type and size.

Production Volume and Cycle Time:

Gate design affects throughput and cycle times. For high-volume production, gates that allow fast filling and rapid cooling may be preferred. In addition, gates that are easy to remove or require minimal post-processing help simplify production.

Cost Considerations:

Gate selection can affect manufacturing costs. Certain gate types may require more complex tooling, resulting in higher upfront costs. Consider overall cost-effectiveness, including tooling, production efficiency, and any secondary operations required for gate removal or finishing.

5. Injection Molding Gate Design Best Practices

– Gate-to-part relationship:

The gate-to-part relationship in injection molding refers to how the gate interacts with the molded part. It involves the gate’s location, size, and design in relation to the part’s geometry and requirements. It affects filling, aesthetics, material behavior, and post-processing. Careful consideration of the gate-to-part relationship is crucial for achieving optimal part quality and production efficiency.- Gate size and shape: Factors to consider when determining gate dimensions and geometry.

– Weld lines and flow patterns:

Weld lines are visible seams formed when molten plastic flow fronts meet. Flow patterns describe the paths of molten plastic during injection molding. Both impact part quality and require careful consideration.

– Venting:

Venting in injection molding involves the incorporation of channels or vents in the mold to allow the escape of air and gases. Proper venting is essential for achieving high-quality parts and minimizing defects caused by air entrapment.

6. Troubleshooting Gate-Related Issues

– Common gate-related defects in injection molding can include gate blush, gate vestige, and gate drool. Here’s a brief description of each:

Gate Blush:

Gate blush, also known as gate blush marks or gate haze, refers to a discoloration or hazy appearance around the gate area on the surface of the molded part. It occurs when the gate is too hot, causing localized overheating and degradation of the plastic material. Gate blush can be more noticeable in transparent or light-colored parts.

To mitigate gate blush, Adjusting injection parameters, such as melt temperature or injection speed, can help reduce gate temperature and minimize the appearance of gate blush marks.

Gate Vestige:

Gate vestige, also called gate witness or gate scar, is a visible mark or indentation left on the part after the gate is removed. It occurs when the gate is not cleanly trimmed or when excessive material remains at the gate location.

To minimize gate vestige, selecting appropriate gate designs that allow for easy removal, optimizing gate location, and controlling gate size are important. Proper gate trimming techniques and tools can also help achieve clean gate removal and reduce vestige.

Gate Drool:

Gate drool refers to the occurrence of molten plastic droplets or strings forming at the gate or nozzle during the injection molding process. It can result from high melt viscosity, improper gate design, inadequate cooling, or excessive heat in the nozzle or sprue.

To address gate drool, optimizing processing parameters, such as melt temperature, injection speed, and back pressure, can help reduce drooling. Proper nozzle design, including the use of shut-off nozzles or valve gates, can also prevent unwanted drooling.

7. To troubleshoot gate-related issues in injection molding:

- Adjust gate size: Increase for better flow or decrease to avoid overpacking.

- Evaluate gate location: Optimize for uniform filling and minimize defects.

- Modify gate design: Optimize flow characteristics or consider advanced designs.

- Ensure proper cooling and venting: Control gate temperature and release air/gases.

- Fine-tune material and process parameters: Optimize for desired flow and packing.

- Maintain the mold: Clean, inspect, and align gate components regularly.

8. To maintain consistent gate performance and prevent blockages in injection molding:

- Regularly inspect the gate area for buildup or damage.

- Clean the gate after each production run to remove residue.

- Remove blockages using appropriate tools and techniques.

- Flush the gate system periodically to remove contaminants.

- Check and clean gate components for wear or damage.

- Optimize processing parameters to minimize material buildup.

- Ensure proper alignment of gate components.

- Follow manufacturer guidelines for maintenance and cleaning.

Conclusion:

Injection molding gates play a crucial role in the success of plastic part production. By understanding the different types of gates, their design considerations, and troubleshooting techniques, you can optimize your injection molding process and achieve high-quality parts. Remember to consider factors such as part design, material properties, production volume, and aesthetic requirements when selecting the appropriate gate type and design. Continuous learning, experimentation, and collaboration with experienced molders will further enhance your understanding of injection molding gates and drive improvements in your manufacturing processes.