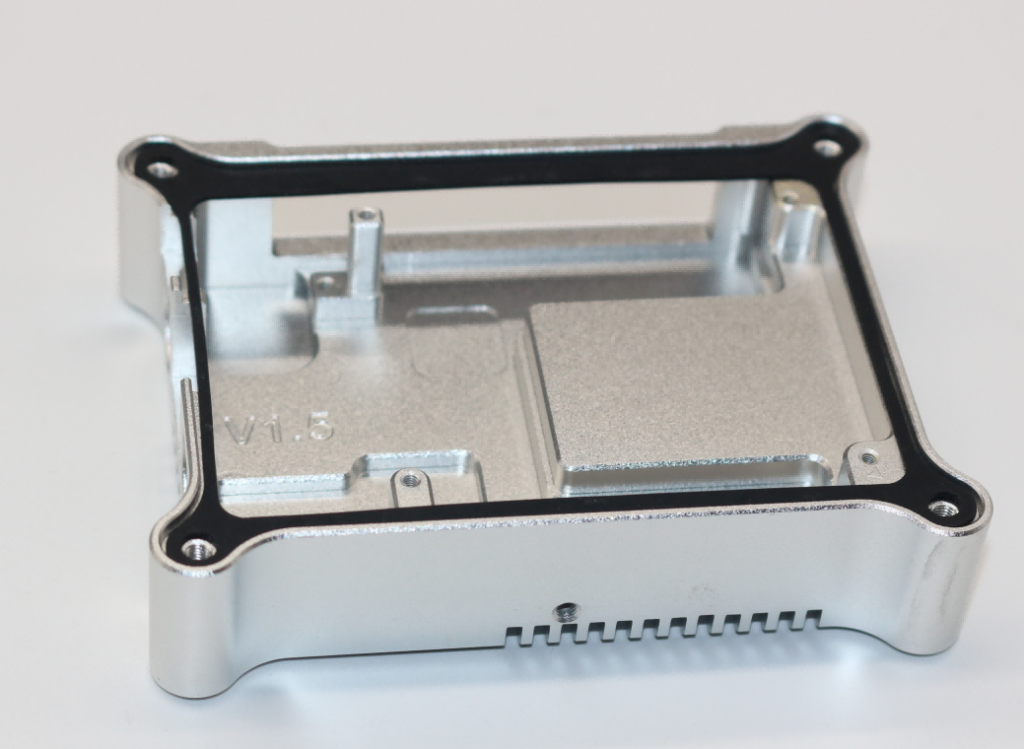

The first impression of any CNC machined part lies in its external appearance and visual representation to onlookers. This crucial aspect has led modern industrialists and manufacturers to prioritize the aesthetics and functionality of their products.

To achieve the desired aesthetic appearance, manufacturers turn to surface finishing treatments for their CNC-machined parts. Surface finishing is a comprehensive and effective process that eliminates outer remnants, scars, threads, blurs, and any unaesthetic marks from the surface of the products.

By employing surface finishing techniques, manufacturers can greatly enhance the overall quality and appeal of their CNC-machined parts. The treatments not only remove imperfections but also provide additional benefits such as improved durability, resistance to corrosion, and enhanced performance.

In this article, we aim to provide you with an overview of common surface finishes available for CNC machined parts.

Varieties of CNC Machining Surface Finishes

Some manufacturers need extreme surface finishing, and the rest require very little. Keeping this point in mind, there are three categories of surface finishing for CNC-machined parts. Find out which one is suitable for your expectations and appeals to your customers.

1. As Machined Surface Finishes

Machining finishing is a very affordable option for manufacturers because it does not incur any extra cost due to being done by a CNC machine.

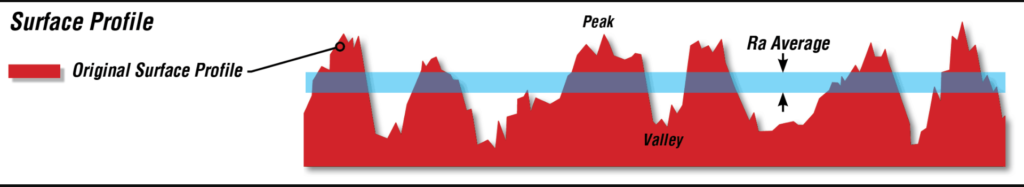

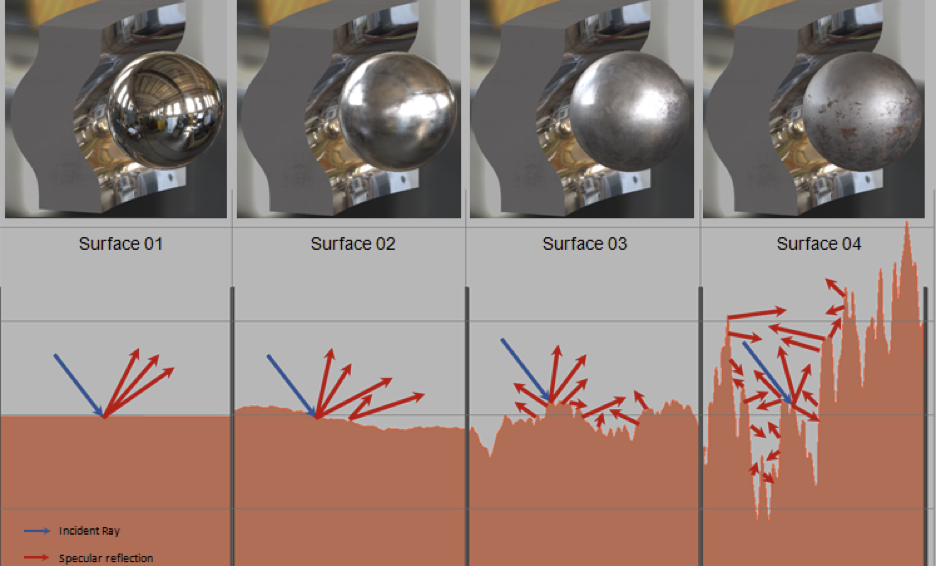

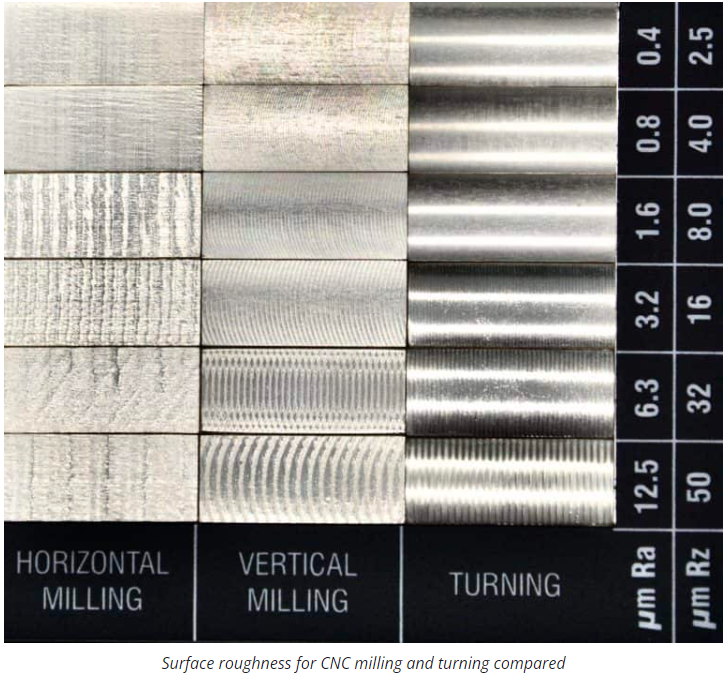

This surface finish is counted in terms of the Ra factor, which is the surface roughness that is defined as the deviation of a machined profile from the ideal surface.

Ra is the foundation of the calculation of surface finish, surface integrity, waviness, and flatness. Some ideal values of Ra are 3.2, 1.6, 1.8, and 0.8 micrometers. The lower the value of Ra, the higher the dimensional accuracy or tolerances.

Machining finishing is the best for those who have a tighter budget. However, it keeps the surface of CNC-machined parts filled with tool marks. In this way, it is not perfect for high-value projects.

2. Chemical Surface Finishes

Coating the surface of CNC-machined parts with another material is termed “chemical finishing. We can say that it is an extra layer of protection against abrasion, corrosion, and external factors.

Chemical finishing offers an aesthetic appeal to the parts because of the addition of their colour, shine, and other similar attributes. Discuss some of its types.

Anodizing

Anodizing is a phenomenon in which the immersion of a part in an electrolyte solution results in the formation of a protective sheath of oxide on the surface. Anodizing sheaths fall into two categories on the basis of applications.

Type I anodizing (up to 25 microns) is perfect for decorative and aesthetic purposes. While Type II anodizing (25 to 150 microns) is great for providing resistance against corrosion and abrasion to the material due to its thick oxide layering.

Alodine Coating

Alodine means a chromate layer, and alodine coating implies the implementation of a chromate thin coating on the CNC machined parts’ surface to boost their capability against corrosion, heat, and adhesion, resulting in an improvement in their longevity and durability. It works very well for aluminum and non-ferrous components.

Black Oxide Coating

Black oxide coating is a surface finishing process in which a black oxide coating is applied to the surface of CNC machined parts throughout for shielding against different contaminants and physical damages.

It improves the capacity to battle corrosion, offers wear resistance, and offers high lubricity. This surface finishing is the best option for steel, copper, and other alloys that form well-bonded bonds with oxygen molecules.

Electroplating Surface Finishes

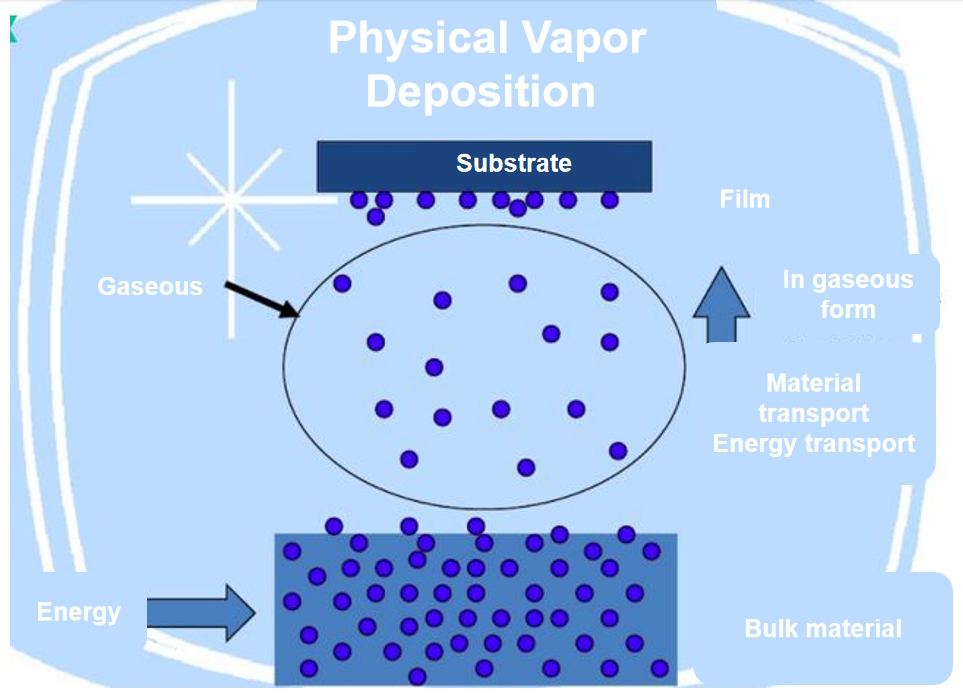

Electroplating consists of two words: electric and plating. It involves the deposition of a metallic sheath throughout the surface of a part with the help of passing electricity to reach its melting temperature.

Electroplating is a very effective protection for the workpiece and protects the inner components from all kinds of contaminants and corrosive impacts.

3. Mechanical Surface Finishes

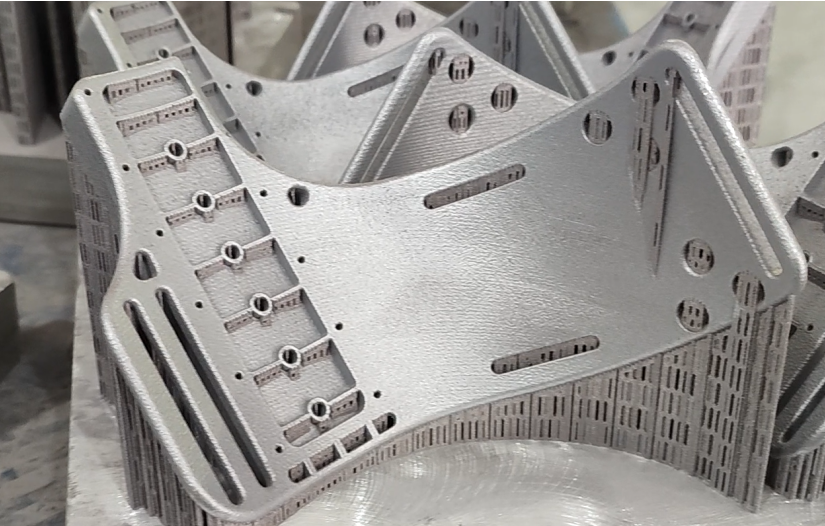

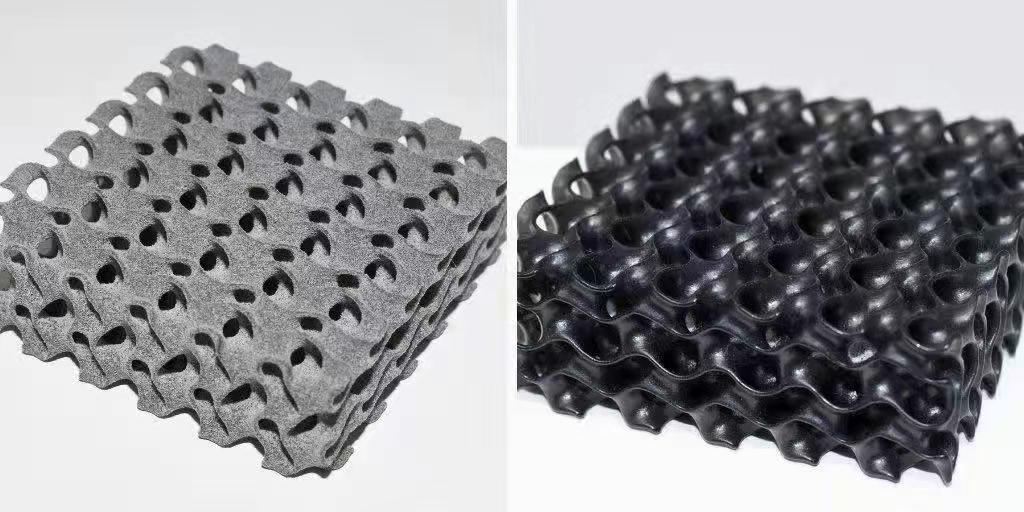

Under mechanical finishes, workpiece undergo multiple cycles of stresses and abrasions with corresponding treatments to obtain a smooth surface on the final products. See its types below.

Bead Blasting

Bead blasting involves the bombardment of spherical beads of glass or ceramic on the surface of CNC machined parts to get their textured, matte surface finish, eliminate imperfections, and create their uniform appearance.

Powder Coating

Attempt to layer a waxy powder on the surface of a part to make it durable and receive its versatile performance. Such powder coats are capable of resisting scratches and chips and do not become obsolete over time.

Brushing

It is a kind of surface treatment, rather than surface finishing. It harnesses a metal-wired brush or an abrasive pad to clean the surface and physically throw out all contaminants or particles on the surface of the parts.

Painting

The use of lacquer and polyurethane in their liquid form to apply over the surface of CNC machined parts to protect the surface from exposure to water, contaminants, dirt, and atmospheric irregularities is known as painting.

Painting CNC surface finishing is a great option to improve the lifespan by keeping corrosion and abrasion at bay by covering the whole external body of a part.

In conclusion, surface finishes for CNC machined parts are instrumental in achieving the desired quality, functionality, and aesthetics. By utilizing the appropriate surface finishing techniques, manufacturers can enhance the performance, durability, and overall value of their CNC machined components.